SIKO supports development project for autonomously operating harvesting vehicle in fruit orchards - Autonomous robot for harvesting apples

Measurement and sensor solutions from SIKO are not only found in established industrial applications, SIKO GmbH is also currently supporting an agricultural research and development project with two rotary encoders from its range for mobile machines.

Developing Nondestructive Sensors for Quality Control

Farmers on the cutting edge of agriculture often use advanced techniques to evaluate their crops. Rather than cutting open fruit and sending the samples to a lab, some farmers have begun using nondestructive methods for quality control.

Cranberry Farm Goes High-Tech

Previously, Lee relied on hand-held digital and mercury thermometers to monitor the bogs' nighttime temperatures, but he wanted a more autonomous and hierarchical system that allowed for continuous monitoring of multiple variables.

How Can Smart Technology Benefit Vertical Farms?

Smart technology can benefit many industries and application areas. IoT (specifically sensors), smart systems used to control and monitor conditions, drones, and predictive analytics are all hugely beneficial, particularly for the vertical farming sector.

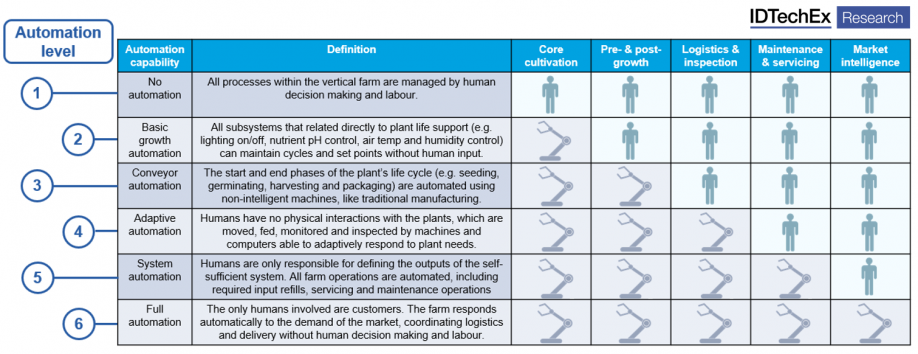

Advancing Automation Technology Could Help Vertical Farms Achieve Profitability, Finds IDTechEx

By using extensive sensor networks for monitoring crops and growing systems, vertical farms can optimize their workflow by helping operators efficiently pinpoint problems. This would serve to reduce labor complexities and thus manpower required.

Control Grow Conditions Like a Millionaire Without Spending a Fortune

Technology breakthroughs and innovative design have resulted in a new way to monitor and control the future of food production. Ensora Systems powers its monitoring and communications with any light - from LED light to sunlight.

Future Crops Brings Vertical Farming Closer to the Land

New agri-tech vertical farm system is reshaping agriculture to sustain the growing population with high-yield crops

"Growth Turbo" CO2 - How Does CO2 Fertilisation Work in the Greenhouse?

Higher yields can be achieved by artificially increasing the CO2 concentration in the greenhouse, especially for vegetables. This offers greenhouse operators an enormous competitive advantage compared to outdoor cultivation.

Cosy Climate in the Greenhouse - Climate Sensors Ensure Optimum Growing Conditions

CO2, humidity and temperature sensors must provide accurate and reliable measurement results to the climate control system in the greenhouse. Inaccurate or even false readings impact on productivity and, in the worst case, can jeopardize the entire harvest.

Integrating Sensors Key to Improving Environmental Conditions for Growing

When precision is needed to improve the yield of a grow room, consider all the factors that must be controlled. Integrating sensors to monitor these attributes are key to improving the environmental conditions of a grower.

Freight Farms and Sodexo Announce Strategic National Partnership to Grow Food Onsite at School Campuses Across the U.S.

With sustainability and transparency in mind, partnership will enable year-round on-campus food production at university and K-12 educational institutions and other national Sodexo clients.

How Curating Weather And Soil Data Can Produce Actionable Environmental Intelligence

As the availability and volume of data to help us understand what is happening or will happen in an agricultural field or orchard continues to grow exponentially, the challenge we now face is how to collect, synthesize and use this data.

Top Article for 2019 - Smart Sensors in Farming

By positioning sensors, farmers can understand their crops at a micro scale, sustain resources, and reduce environmental impact.

Automated Commercial Containers for Cannabis Cultivation

With our B2B commercial model, we have developed automated commercial containers for the cultivation of both medical cannabis, as well as vegetables and herbs.

New HOBOnet Field Monitoring System from Onset Enables Cost-Effective Cloud-based Monitoring of Environmental Conditions across Fields and Greenhouses

HOBOnet gives growers and researchers greater visibility into field conditions with near real-time data from wireless sensors, alert notifications, and access via mobile devices

Records 1 to 15 of 34

Featured Product

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.

.jpg)

.jpg)