The research and development team is always on the lookout to try various crops that have yet to be grown in a hydroponic Tower. It was a first for our grow team to trial broccoli in the ZipFarm, so we removed all expectations.

Hydroponic Broccoli – Seed to Harvest Trials

Hydroponic Broccoli – Seed to Harvest Trials

Case Study from | ZipGrow Inc.

Broccoli comes from the Brassicaceae family. The Brassicaceae family consists of mostly herbaceous plants, and some grow as small shrubs. The leaves are simple in design and can grow quite large.

Broccoli can produce large ascending leaves that may reach 12 – 24 inches long. The flowers for both vegetables develop into a tightly compact bundle in the center of the crop. Those tightly compacted bundles of flowers are what we harvest and find on our grocery store shelves.

In traditional soil growing, broccoli typically matures into an edible head after 60 – 70 days.

Growing broccoli in hydroponic Towers.

The research and development team is always on the lookout to try various crops that have yet to be grown in a hydroponic Tower. It was a first for our grow team to trial broccoli in the ZipFarm, so we removed all expectations. We are happy to share our experiences with you.

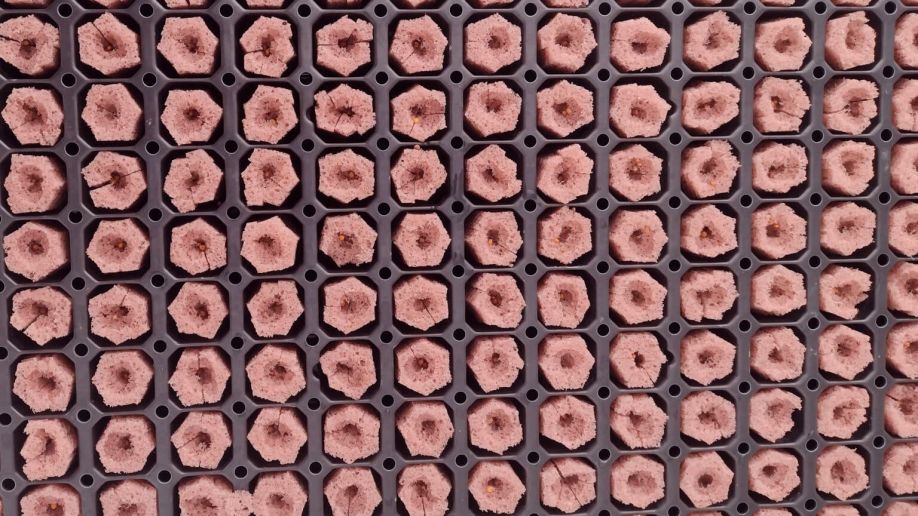

The seedlings were set in biodegradable GrowFoam® plugs to germinate.

Eighteen days later, the seedlings were transplanted into the eight-foot-tall vertical Towers.

The first heads of broccoli were ready for harvest after eleven weeks (around 75 days).

The average width was 18 inches, and the height averaged 22 inches.

Due to the large stature of these crops, the team accounted for spacing two feet between each head. Some bigger leaves began to overlap and grow into one another, a defoliation was scheduled after the ninth week in preparation for its harvest.

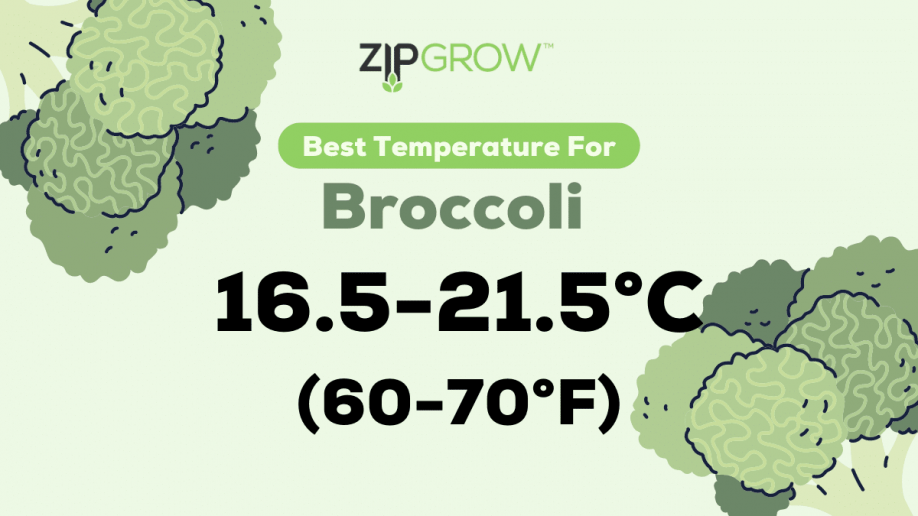

The team referred to credible online sources regarding outdoor field production of broccoli. The indoor climate was conditioned and optimized as best as possible to mimic the growth cycle of an outdoor crop. The goal was to promote vigorous root and shoot growth throughout the development cycle.

With all the climate inputs set in place, the whole heads of broccoli came out successfully.

With the conclusion of the crop trial, the grow team recommends maintaining a cool climate between 16.5 – 21.5°C .(60-70F).

Grower Tips

- Remove two to three leaflets per plant to help with aeration control.

- Be wary of vegetative growth choking out the flower heads, as this will lead to trouble when preparing for the expected harvest date.

- Good aeration also helps with controlling mildew outbreaks.

We typically don’t grow large-stature crops in ZipGrow Towers as they take up quite a bit of space; they don’t make the best use of the canopy. Because of this, we recognize that these types of crops may not be financially viable as an ongoing crop option for a full-scale commercial farm. They are, however, a great feature addition in CSA boxes or grown for personal use.

The broccoli grew healthy and of good size and color, and like all of the produce we grow, the controlled environment allowed us to grow them with 95% less water and without the use of pesticides and herbicides.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product